NOISE ![]() VIBRATION

VIBRATION ![]() HARSHNESS

HARSHNESS

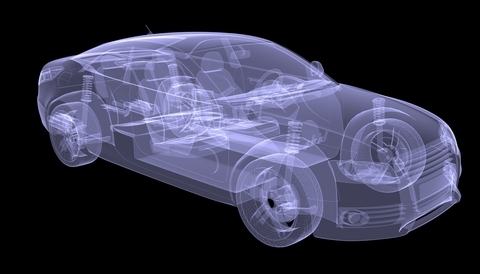

Insulating automobile occupants from noise, vibration and harshness requires

skilfully designed components that are molded from a variety of rubber materials as well as composites that include rubber bonded to metals.

Utilizing special multi-cavity rubber injection equipment with capacities up to 500 tons, WEGU molds a wide range of purpose-designed components that permit automotive engineers to meet or exceed NVH objectives.

This category of component is required to withstand a variety of combinations of constant or shock load, heat, chemical and environmental conditions. Metal structural components, properly pre-treated, can be securely rubber encapsulated in WEGU’S single pass process.

WEGU is committed to the development and production of superior rubber and rubber bonded to metal products that surpass our customers’ expectations.

- Body cushions

- Control arm bushings

- Drive shaft couplings

- Exhaust system

- Jounce bumpers

- Radiator support insulators

- Shifter isolation bushings

- Shock absorber bushings

- Spring insulators

- Stabilizer bar bushings

- Strut seats

As leaders in the automotive rubber molding industry we offer complete product development. Our extensive laboratory facilities permit rapid testing and design specification verification on both the prototype and finished part.

Please contact us for your specific requirements.